Servos are an electrical component used in every type of RC vehicle, from aircraft to cars, boats, and robots. Specifically, RC car servos allow the vehicle to steer.

With so many different servos on the market, people often ask if all RC car servos are the same or if there are different types for various applications?

How do RC servos work, and are there any different types you need to be aware of to enhance the performance of your RC car?

What Does A Servo Do On An RC Car?

A servo is an electric actuator with either linear or rotational motion to move or control an aspect of the radio control car.

Servos control RC aircraft’s rudders, flaps, ailerons, elevators, and other flight controls. An RC car is a little less complicated from a servo point of view, having servos mostly to control the vehicle’s steering.

Servos are a relatively cheap component to manufacture, making them a reasonably inexpensive part of an RC car to upgrade or replace.

Are all RC car servos the same, or are there different types of servos you need to consider when upgrading your car or replacing parts?

RC Car Servo Guide: Overview

Several types of servos are available for RC car hobbyists. They’re generally broken down into size, signal type, and servo arm action.

Considering most quality RC servos cost between $40 and $100, you want to be sure you’re choosing the right servo for your RC car.

Analog or Digital RC Servos

The main difference between an analog and digital RC car servo is how they process signals and control the car’s steering.

Analog RC servos operate by sending a continuous electrical signal to the motor, which determines the position of the wheels.

For example, if the signal strength is low, the servo motor will turn the wheels in one direction. In contrast, a stronger signal will cause the wheels to move in the opposite direction. Since an analog RC servo motor continuously receives a signal, it adjusts the wheel’s position in real-time based on the signal’s strength.

Digital servos, on the other hand, use a microprocessor to convert incoming signals into steering commands. This means they provide more accurate positioning, faster response times, and greater torque than analog servos.

They can also hold their position more accurately and are less likely to suffer from “servo chatter” (small movements or vibrations when the servo is at rest).

Overall, digital servos are considered better than analog servos. RC drivers who demand more steering precision typically opt for a digital servo.

RC Servo Specifications: Torque & Speed

When shopping for RC servos, pay attention to these two servo specifications: torque and speed. They will significantly impact the vehicle’s performance and handling.

RC servo torque ratings refer to the servo’s ability to produce a twisting force. This is measured in units of force multiplied by distance, such as ounce-inches or kilogram-centimeters.

We’re specifically referring to how much force it can apply to the car’s wheels. A higher torque rating can allow the car to move heavier or larger wheels with greater force.

This is important for RC cars requiring more power, such as crawlers.

A servo’s speed refers to how quickly it can move the car’s wheels. A servo with a higher speed rating can turn the wheels faster and with greater precision, which can be important for RC cars that require quick, precise movements, such as those used for on-road racing.

It’s worth noting that a servo with a higher speed rating may not have as much torque as one with a lower speed rating. Finding a balance between speed and torque is important for optimal performance.

Additionally, the servo’s size and weight will also impact the RC car’s performance.

A heavier or larger servo can add weight to the front or rear of the car, which can impact its balance and stability. This can be important for RC cars that require a specific weight distribution for optimal performance, such as those used for drifting or racing.

RC Car Servo Arm Action

There are 3 main servo action types, depending on the intended function of the servo. These 3 action types are linear, rotational, and continuous rotation actions.

The linear function servo has a push-pull action. A rotational servo rotates forward and back, and a continuous rotation servo can spin continuously, similar to an electric motor.

The type of servo action you select for your car will depend on what the servo is designed to do on the vehicle.

Linear push-pull servos are primarily used to steer an RC car. When an electrical signal come in, the servo output shaft turns one direction or the other to turn the car’s wheels.

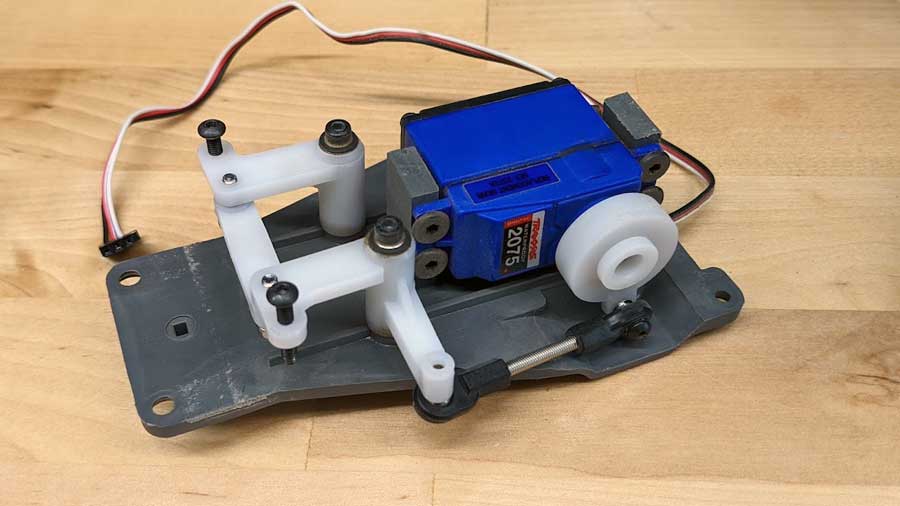

Servos generally work with other moving parts to achieve the action required in the RC car. These can be cogs and gears, levers and joints, or stiff wire components extending the servo’s reach into the vehicle’s body.

When replacing a servo, ensure the replacement servo has compatible connection points for your associated parts.

Are RC Servos Interchangeable?

Generally speaking, yes. You don’t need to buy the same brand and model for compatibility when replacing your RC car’s servo.

It’s common for RC car owners to upgrade their standard servo to a high-performance unit from third-party servo manufacturers.

However, you do need to make sure the servos have the same physical dimensions and mounting points.

Most RC car servos use a standard mounting pattern and connector size, so servos from different manufacturers can usually be interchanged with each other. However, check the specifications of the servo to ensure that it is compatible with the RC car’s receiver and transmitter.

Servos with different torque ratings, speed ratings, and degrees of rotation may perform differently, even if they are physically compatible with the RC car. This may cause other components in your RC car to fail.

Before installing a new servo in your RC car, check the specifications to ensure that it is compatible with the RC car and meets the performance requirements of the specific application.